Step Into the World of Meir

Join us on a journey while we create bespoke pieces from beginning to end, and discover the world of Meir difference.

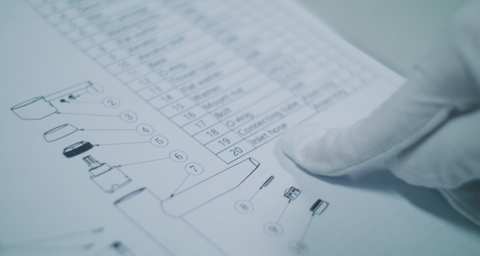

Each product consists of many complex and high-quality components ranging from local to European sources.

Every part is carefully assembled from beginning to end, to provide the final result; a flawless product.

The onsite foundry allows us to mould and craft products to our extremely high specifications.

Care and consideration is used by expert moulding staff to ensure safety levels are maintained at a very high standard.

We only select the highest quality DZR brass for manufacture, as well as recycling 100 percent of waste and unused brass.

Each piece is carefully hand-crafted and assembled by expert production line staff who have been with the company for many years.

Once a piece has been expertly crafted by hand, it is polished with ultimate precision to remove imperfections and a clear coating is applied.

Our products are consistently finished in a clear protective layer coating, to ensure they do not patina over time.

The electroplating and PVD process which all of our products go through, uses state-of-the-art machinery that is environmentally friendly and ensures consistency in colour finishes.

Meir’s assembly line consists of thorough quality control measures and processes that ensure minimal defects.

Our passionate, artisan metal workers are dedicated to ensuring every product is hand-crafted with ultimate precision.

Every product is manufactured under strict quality control measures to ensure superior excellence and comply with Watermark, WELS, WRAS (UK) and SABS (South Africa) certifications.

After assembly our team conducts thorough final inspections on every piece to ensure customers receive a flawless product each and every time.

The packaging used consists of a high-density, laser-cut foam insert in a strategically created box, designed to excite the senses.